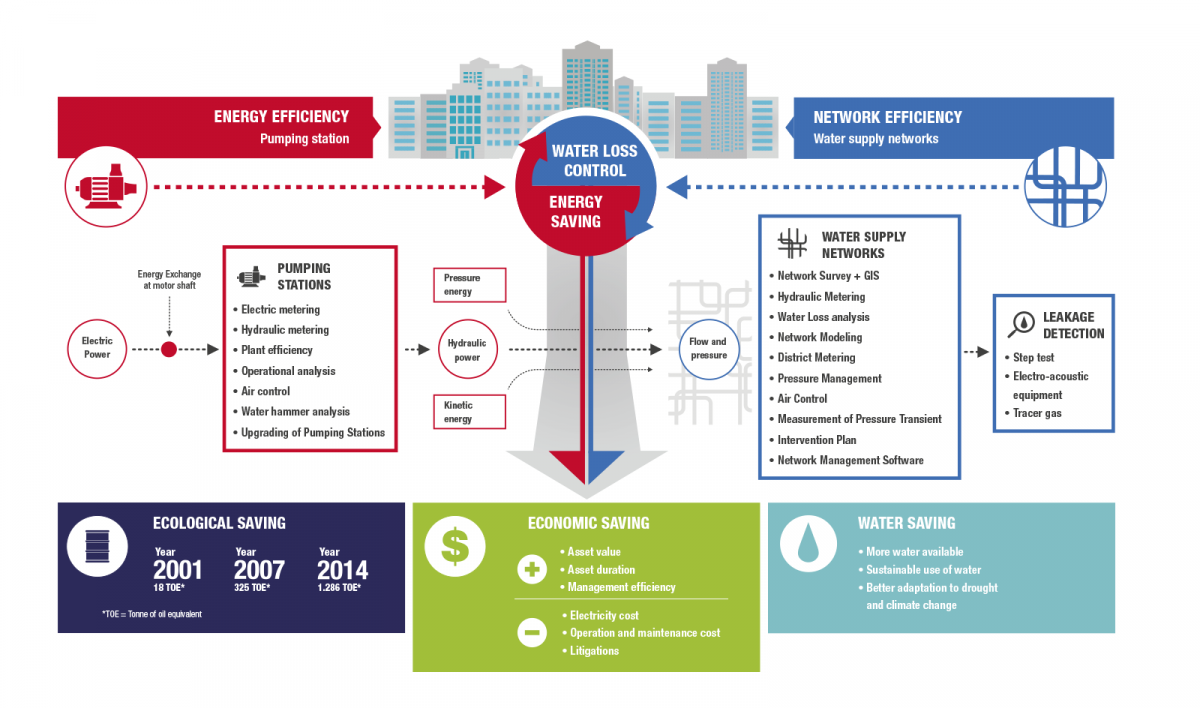

Topographic survey of the network and building of GIS and database containing all the necessary information of the efficient management of water supply system. Elaboration of hydraulic and functional schemes of the distribution system useful for DMA (district metering area) and SCADA design.

Flow and pressure monitoring using own portable equipment for verification of hydraulic parameters, model calibration, quantification of nocturnal minimum consumption and water balance.

Measurements of pressure transients using special equipment at very with high frequency of acquisition (5/100 ") Pressure transients and water hammer are responsible for the progressive deterioration of pipelines and hydraulic devices and generate at the same time an increasing of water loss frequency.

Evaluation of physical and Commercial losses

Evaluation of physical and Commercial losses using IWA water balance and analysis of Minimum Night Flow

Building and calibration of the mathematical model of the water distribution systems as a supporting tool for network management and design of interventions. The calibrated model is used for the performance analysis of the water network under different conditions, DMA design, operational optimization, handling of emergency situation and design of hydraulic upgrading and rehabilitation.

Design and implementation of District Metering Areas (DMA) in order to improve leakage control and the maintenance of the water network. Flow and pressure measurements to check DMA isolation and valves water tightening. Design of intervention and procurement management for permanent DMA implementation.

Design and implementation of pressure management in order to reduce water loss and optimize network management. Technical advice and assistance for the selection, setting and calibration of the most suitable devices to obtain the expected pressure regulation.

Leakage detection is carried out through the implementation of two steps: leakage pre-location to find areas with higher level of leakage and leaks pinpointing.

Leakage pre-location

Leakage pre-localization is performed with the Step-Test analysis (subdivision of the network into sectors and monitoring of inlet flow during the progressive isolation of the single sectors overnight). As an alternative to Step-Test, the deployment of noise loggers along the network is useful to identify areas with possible losses.

Leaks pinpointing

Leaks pinpointing is generally obtained with the use of acoustic equipment like correlators and ground microphone. Tracer gas is preferred under conditions of low pressure. Leaks location for large diameter pipes is carried out using correlation with hydrophones.

Air control and prevention of pressure transients

Air in pipelines determines several problems like: pressure transients and hence risk of failure, flow reduction, reduction of pumping stations efficiency, cavitation, error in flow metering.

To reduce these problems, we carry out an accurate network analysis aimed at the identification of the optimal locations for the installation of suitable air control valves. At the same time, to reduce pressure transients and guarantee the protection from possible water hammers, we carry out the technical-economic analysis of the most suitable protection systems.

Delivering of operative procedures for the management of water network, water loss control and maintenance of achieved results

Flow and pressure measurement at the pumping stations, pump test.

Metering of Power, Voltage

Calculation of Plant Efficiency

Calculation of energy efficiency based on the actual power absorbed by the pumping system, measured by the electrical panel board.

Continuous monitoring of the pumping station operation for a multiday period.

Measurement of pressure transient with high frequency pressure loggers (5/100"). Evaluation of pressure transient frequency and magnitude and selection of the most suitable systems and devices for protection from water hammer.

Pumping station upgrading to improve energy efficiency

Design of intervention aimed at energy efficiency such as installation of inverters, installation/replacement of high efficiency electromechanical equipment, pump operation optimization. Cost-benefit analysis and calculation of payback period. Assistance in obtaining Energy Efficiency Credits.